TSMC semiconductors A major reason why manufacturers are setting up factories in the United States is to avoid geopolitical risks, but they also have to accept the challenges brought about by rising operating costs.

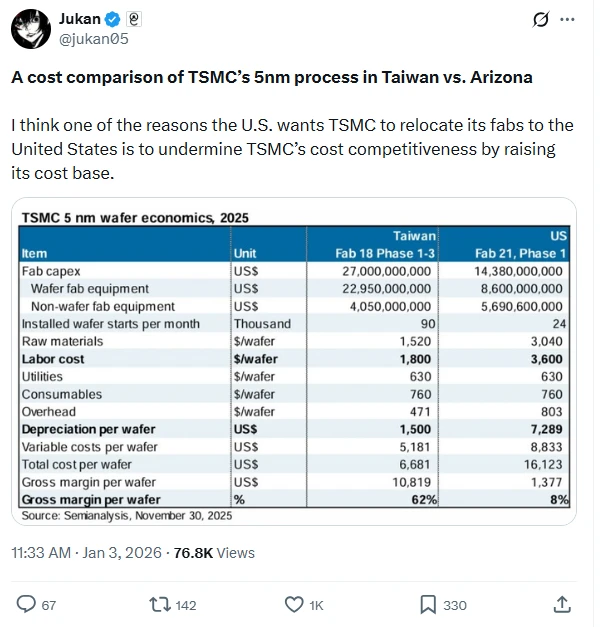

According to data compiled by SemiAnalysis and shared on the X platform by analyst Jukan, TSMC's profit margins will suffer significant losses from manufacturing chips in the United States. He also wrote that he believes one of the reasons the US wants TSMC to move its wafer fabs to the US is to increase the company's costs and weaken its competitiveness.

Specifically, TSMC's gross margin per wafer for 5nm chips produced in Taiwan is 62% compared to that produced in the United States, a difference of 54 percentage points. Depreciation and labor costs are the main reasons for this difference.

Depreciation refers to the spread of the purchase cost of a wafer fab and its equipment over its useful life, with the specific difference reflected in the total output over the lifespan. Data shows that a US fab producing wafers using the same technology may only produce a quarter of the output of a Taiwanese fab, meaning that the depreciation cost of a US fab is nearly four times that of a Taiwanese fab.

Economy and Politics

Last August, US President Trump stated that TSMC might invest $300 billion in Arizona, including building wafer fabs, advanced packaging facilities, and R&D facilities there. This figure is nearly double the total investment TSMC had previously announced in the United States.

TSMC's move is in line with the US government's "America First" economic agenda and also to ensure that geopolitical factors do not affect the company's supply. However, building a stable supply chain in the United States could take decades.

Furthermore, considering construction and operating costs, TSMC's US wafer fab needs to generate more revenue to cover expenses, requiring TSMC to continue investing capital. On the other hand, high labor costs are also increasing the burden on the US factory.

Morris Chang, former chairman of TSMC, once said that if equipment malfunctions at 1 a.m., the Taiwan team can repair it by 2 a.m., while the United States has to wait until the next morning. This is a difference in work culture.

From an efficiency and economic perspective, TSMC prefers to hire engineers from Taiwan to work in the United States, but this also raises some policy issues, as the US government hopes that TSMC can promote local employment in the United States.

"Made in America," driven by political factors, is now facing a critical test of its economic viability. Last November, reports indicated that TSMC's latest quarterly profit from its US operations had fallen sharply from NT$4.232 billion to NT$41 million.

(Article source: CLS)